In each refinery, factory or plant for processing, there’s a process that is quietly moving fluids day in and day out without pause. Industrial pumps aren’t seen until there’s an issue, yet they are essential to the modern industrial. The best industrial centrifugal centrifugal pumps or choosing the right screw-pump and pump-parts manufacturer could result in a smooth and cost-effective operation.

Image credit: lepuseal.com

Industrial pumps are constructed for environments where reliability matters more than anything else. These machines are designed to move fluids, such as water, chemicals and oils through complicated systems. Industrial pumps are constructed for continuous use and extreme conditions. They do not allow for any shortcuts.

Understanding Centrifugal Pumps and Screw Pump Applications

Centrifugal pumps are among the most commonly employed types of industrial pumps. The simple design of centrifugal pumps and their consistent flow, and their efficiency in energy use make them an excellent choice to move large quantities of low-to-medium viscosity liquids. This is the reason why a lot of industrial centrifugal pump manufacturers focus heavily on refining impeller geometry along with casing materials and the performance of their motors. These improvements decrease energy consumption and allow for consistent output throughout long operating times.

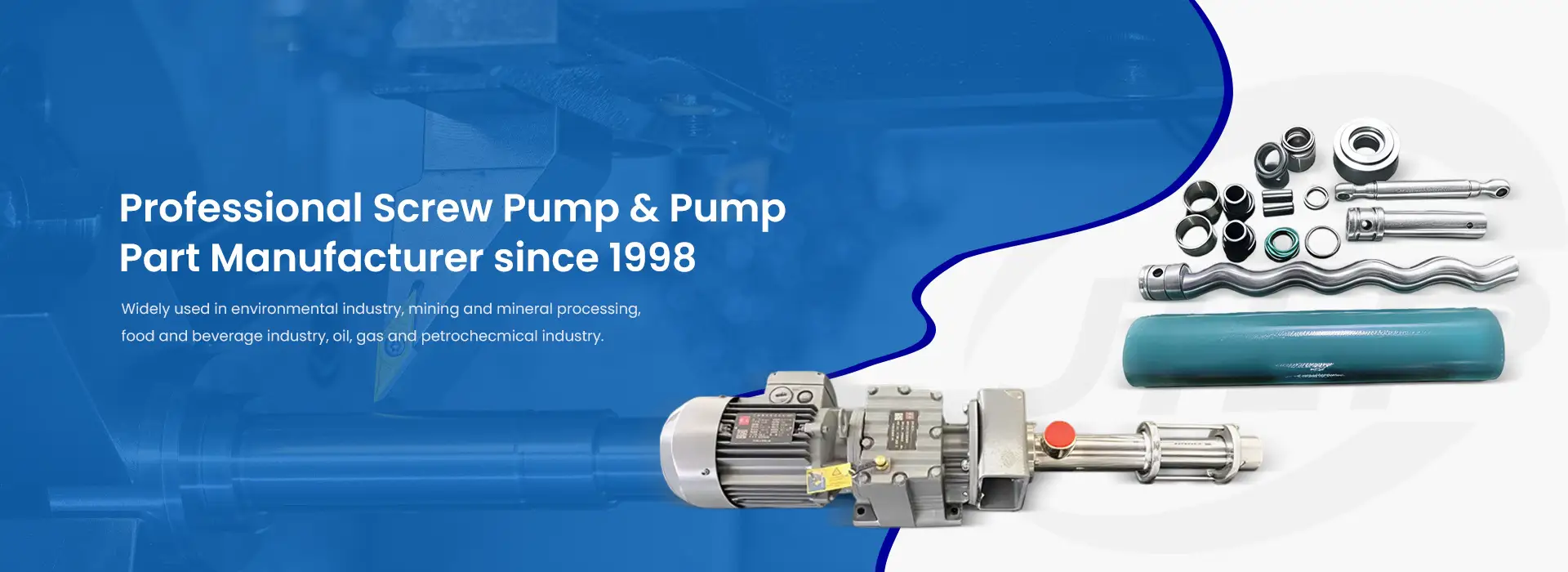

Screw pumps serve a different, yet equally crucial, function. They are ideal for situations in which consistency is a concern, especially when dealing with more difficult, thicker substances. Screw pumps ensure fluid, smooth and pulse-free movement for viscous chemicals, oils and sludges. A specialized screw pump & pump parts manufacturer understands how internal tolerances, rotor design, and sealing systems influence performance and lifespan under pressure.

Together, these pump types offer a broad range of industrial requirements, ranging from simple water transfer to more complex processes and chemical handling.

Pump parts are more crucial than most people believe.

A pump’s reliability is determined by the parts inside. Mechanical seals, shafts casings and bearings are subjected to constant pressure, friction and wear. As time passes, even the smallest malfunctions in the component can result in vibration, leaks or even system shut downs. A supply of top-quality components is as essential as having a reliable pump.

Many industrial operators prefer to partner with suppliers who offer complete solutions for pumps, rather than procuring parts from a variety of vendors. If you have compatible and well-constructed parts on hand, you can reduce downtime while extending the life of your equipment. This system also makes it easier to follow maintenance plans and permits systems to operate within specification.

This is the reason Lepu Seal, your one-stop source for pumps and pump parts, has emerged as an essential choice for industrial buyers. With the ability to offer complete pump systems as well as a wide selection of replacement parts, Lepu Seal supports long-term operational stability across industries.

For Industries That Can’t afford downtime

Pumps are commonly utilized in refineries, chemical plants and manufacturing facilities. They are also used in the energy and wastewater system as well as operations. In these settings, failures can be a source of frustration they can also cause disruption to whole production processes. This is why standards for manufacturing tests, procedures for testing, and quality control play crucial roles.

Before delivering, reliable manufacturers test their pumps under real operating conditions. The pressure checks, inspection of the material and the performance tests make sure that each unit meets the high standards. This attention to details allows industrial customers to work confidently, knowing that their equipment is built to last.

The need for reliable components and long-lasting pumps is likely to grow as industries continue to modernize and expand. Industrial Centrifugal Pump Manufacturers who have solid track records and reliable pump part suppliers can ensure that the systems are durable, efficient and ready to meet the demands of continuous operation. Reliability doesn’t just happen to be an attribute, it’s the foundation of industrial success.